In any automated plant—be it packaging, automotive, metals, FMCG, or material handling—limit switches are tiny devices with outsized responsibility. They tell a machine where to stop, when to start, and whether a guard, gate, or actuator is exactly where it should be. Done right, they prevent accidents, reduce downtime, and extend equipment life. This guide explains how limit switches work, where they add the most safety value, how they boost reliability, and what to look for when selecting them—plus why BCH Electric is widely regarded as one of the best limit switch manufacturers in India for demanding applications.

What Is a Limit Switch?

A limit switch is an electromechanical device that detects the presence, position, or end-of-travel of a moving part. A mechanical actuator (plunger, roller lever, whisker, etc.) changes the state of internal contacts (NO/NC), which can be used to:

-

stop a motor at end-of-travel,

-

interlock safety guards and doors,

-

confirm part presence before a process,

-

home an axis for repeatable positioning.

Limit switches are favored for their simplicity, robustness, and dependable repeatability in harsh environments where dust, moisture, vibration, or oil might challenge non-contact sensors.

7 Ways Limit Switches Improve Machine Safety

-

Physical End-Stop Protection

On conveyors, hoists, lifts, and actuators, limit switches define hard end-points. If a drive overshoots due to control faults, the switch can immediately break the circuit, preventing mechanical crashes, belt damage, or cylinder over-travel. -

Guard Door Interlocking

On presses, CNCs, and packaging lines, guard doors must be closed before motion. A limit switch on the door hinge or latch provides a positive indication of the guard’s state, enabling safety logic to inhibit motion when open. -

Two-Hand/Sequence Interlocks

In semi-automatic stations, limit switches ensure the correct sequence (e.g., clamps engaged before cutter moves). This eliminates unsafe shortcuts, reducing operator risk. -

Emergency Return-to-Safe

Strategically placed limit switches help machines move to safe positions after an E-Stop, confirming axes are homed, jigs are parked, or tools are retracted before restart. -

Redundancy & Diagnostics

Dual-channel circuits using two independent limit switches can achieve higher safety performance (e.g., PLd/PL e architectures when integrated correctly), offering fault tolerance and the ability to diagnose discrepancies between channels. -

Prevention of Mechanical Binding

Detecting misalignment at the earliest point (e.g., pallet skew, jam) allows the control system to halt motion and prompt an operator intervention before damage or injury can occur. -

Compliance Support

When designed into a system in line with relevant standards (e.g., IEC 60947-5-1 for control-circuit devices, and risk reduction principles per ISO 12100/13849 at the system level), limit switches help OEMs demonstrate due diligence in safety.

⚠️ Note: Safety performance depends on the entire system design (category/PL/SIL), wiring architecture, and validation—not just the switch itself.

7 Ways Limit Switches Improve Reliability & Uptime

-

Repeatable Positioning

High-precision actuators deliver consistent switching points, aiding accurate homing and end-of-travel detection, which stabilizes cycle times and reduces rework. -

Rugged Construction for Harsh Environments

Metal/engineering-polymer housings, sealed actuators, and IP65/IP66/IP67 ratings (as applicable) protect against dust, coolant, and washdowns—less downtime from contamination. -

Clear Electrical Behavior

Crisp contact action (snap-action mechanisms) yields predictable signal transitions, minimizing controller misreads caused by bounce or vibration. -

High Mechanical & Electrical Life

Quality limit switches are rated for millions of operations and high switching cycles at rated load—ideal for 24/7 duty lines. -

Serviceability

Familiar form factors, replaceable actuators, and standardized mounting make field replacement quick, cutting mean time to repair (MTTR). -

Noise Immunity

Dry-contact outputs are immune to electrical noise plaguing analog sensors. With proper wiring and shielding, nuisance trips near zero. -

Predictable Failure Modes

Mechanical devices often fail detectably (e.g., actuator damage, obvious wear). Condition checks during preventive maintenance are straightforward, enabling planned replacement before breakdowns.

Common Types of Limit Switches (and Where They Shine)

-

Plunger/Plunger with Roller: Compact, accurate end-of-travel for linear movements; ideal on slides, stops, and pushers.

-

Roller Lever / Adjustable Lever: Versatile with cam-driven or rotary motions; easy to set the trip point via cam angle.

-

Whisker/Rotary Spring Lever: Sensitive detection for light parts or fragile components (electronics, FMCG).

-

Fork/Enclosed Safety Interlock: Guard door latching and interlocking with tamper resistance.

-

Heavy-Duty Metal Body: Cranes, hoists, steel plants—high impact/vibration zones.

Selection Checklist: Choosing the Right Limit Switch

-

Application & Actuation: Linear vs rotary motion? Required operating force and pre-travel? Cam profile?

-

Electrical Ratings: Voltage/current, AC/DC, inductive loads; check utilization categories and contact materials.

-

Ingress Protection: Match environment—dust, oil mist, coolant, washdown. Aim for suitable IP rating.

-

Temperature & Vibration: Ensure specs cover min/max temperatures and shock/vibration levels on your machine.

-

Mechanical Life: Look for high cycle ratings; consider duty cycle and expected annual operations.

-

Form Factor & Mounting: Standardized hole patterns and actuator options simplify replacement and upgrades.

-

Safety Architecture Fit: For interlocks, ensure the device and installation support your risk reduction target (e.g., PL level).

-

Certifications & Standards: Conformity to IEC 60947-5-1 (and others as applicable) helps with compliance and audits.

-

Service & Availability: Local support, spares, and lead times directly impact uptime.

Installation Best Practices

-

Use Proper Cams/Stops: Ensure smooth, repeatable actuation; avoid side loading the actuator.

-

Set Over-Travel & Differential: Respect manufacturer guidelines for precise switching and longer life.

-

Protect the Cable Entry: Use cable glands and strain relief; route clear of moving parts and heat sources.

-

Avoid Flooding & Impact: Shield from direct coolant jets and accidental hits; consider protective guards.

-

Label & Document: Mark each switch in electrical drawings; log trip points and maintenance intervals.

-

Test Regularly: Include function checks in preventive maintenance. For safety interlocks, validate both channels and monitor diagnostics.

Troubleshooting & Maintenance Tips

-

Nuisance Trips: Check for misaligned cams, loose mounts, or vibration; use lock washers/thread locker.

-

No Actuation: Inspect actuator wear or bent levers; verify correct wiring (NO/NC) and contact continuity.

-

Intermittent Signals: Examine cable damage, terminal looseness, and controller debounce settings.

-

Early Wear: Reduce operating force, improve cam profile, ensure correct over-travel, or upgrade to a heavier-duty model.

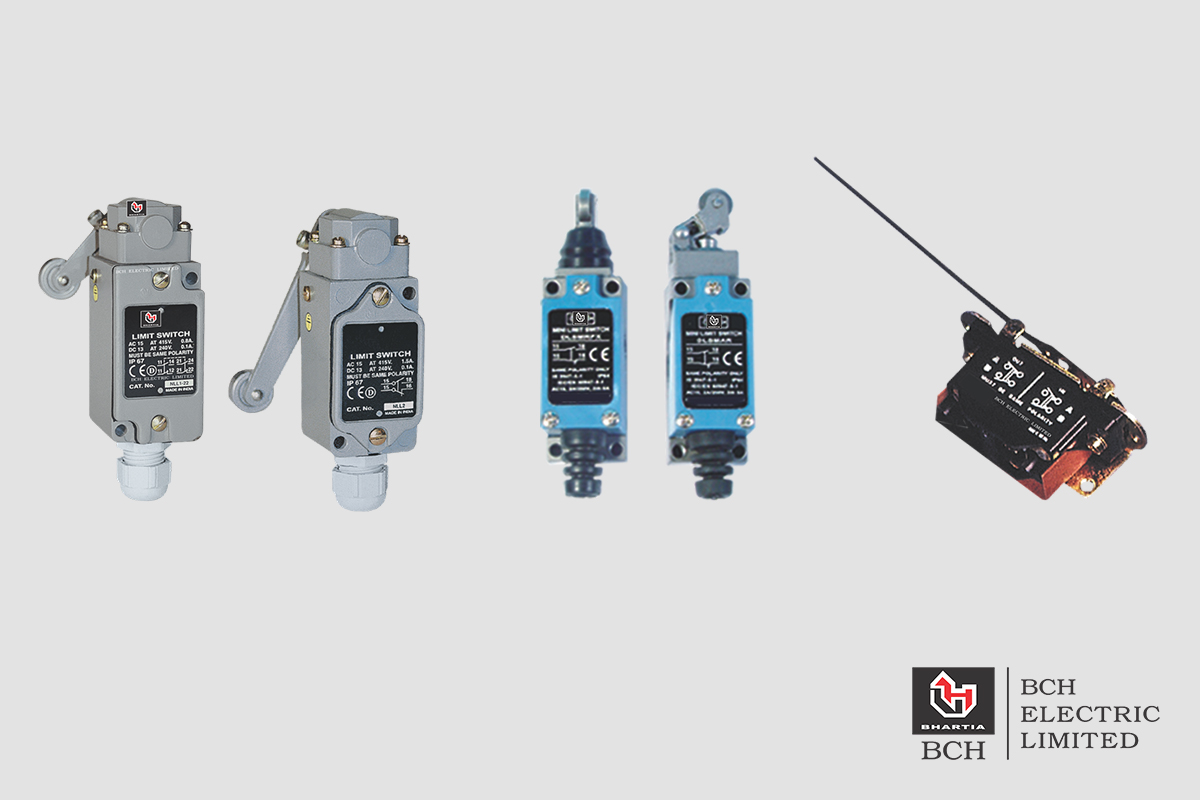

Why BCH Electric Is a Top Choice for Limit Switches in India

BCH Electric has built a strong reputation among OEMs and plant engineers for durable, precisely engineered, and application-ready limit switches:

-

Robust Build Quality: Metal and engineering-polymer housings, crisp snap-action mechanisms, and actuator options for diverse use cases (plunger, roller, lever, safety interlocks).

-

Industrial-Grade Ratings: Models with high mechanical life, appropriate IP protection, and consistent switching performance across demanding duty cycles.

-

Standards-Aligned: Designed to meet relevant IEC requirements for control-circuit devices, aiding documentation and compliance.

-

Made for Indian Conditions: Withstand dust, humidity, temperature swings, and vibration commonly found on subcontinent shop floors.

-

Strong Service & Availability: Pan-India presence, responsive technical support, and reliable spare availability—reduced downtime for maintenance teams.

If you’re upgrading end-of-travel detection, interlocking guard doors, or seeking reliable homing feedback, BCH Electric’s limit switch portfolio offers the performance and support that Indian plants expect.

Mini Case Examples

-

Conveyor End-Stops (FMCG): Replacing worn sensors with BCH roller-lever limit switches reduced over-travel incidents to near zero, eliminating belt edge fraying and saving hours of weekly rework.

-

Press Guard Interlock (Automotive Tier-1): Dual-channel door interlock using BCH safety-rated switches improved functional safety scoring and cut restart delays through reliable diagnostics.

-

Hoist Upper/Lower Limits (Foundry): Heavy-duty metal-bodied switches with reinforced actuators endured heat and vibration, extending mean time between failures by more than a year.

(Illustrative scenarios; verify ratings and safety architecture for your specific use.)

Frequently Asked Questions

Q1. Can I replace a proximity sensor with a limit switch?

Yes—especially in oily, dusty, or high-EMI zones where mechanical contact is more dependable. Ensure the actuation mechanics (cams/levers) suit the motion.

Q2. What IP rating should I choose?

For general industrial indoor use, IP65/66 is common; for washdown or splash zones, consider IP67. Always match to your environment.

Q3. How often should I test safety interlock switches?

Add them to your routine PM (weekly/monthly based on risk). Validate both channels, check contact states, and confirm the machine cannot run with the guard open.

Q4. Why do switches fail early?

Common causes: side-loading actuators, insufficient over-travel, vibration loosening mounts, or exceeding electrical ratings. Address the mechanical setup first.

Q5. Are limit switches suitable for high-speed axes?

For very high-speed/precision axes, consider combining limit switches (as hard end-stops) with non-contact homing for fine positioning.

Conclusion & Next Steps

Limit switches are foundational to safe, reliable automation. They interlock hazards, prevent over-travel, and provide dependable position feedback—all while staying rugged and serviceable. For Indian plants that demand proven performance and local support, BCH Electric stands out as a best-in-class manufacturer of limit switches with the build quality, ratings, and availability maintenance teams rely on.

Considering a retrofit or new machine build?

-

Map each axis and guard to the right actuator type (plunger, roller lever, interlock).

-

Specify IP rating, mechanical life, and electrical load properly.

-

Standardize on a serviceable, India-supported brand like BCH Electric.

CTA: Need help selecting the right limit switch or standardizing your plant bill of materials? Share your application details (motion type, environment, load, duty cycle), and I’ll draft a shortlist with exact part specs tailored to your machine.