In industrial operations, every component matters, especially the wiring that powers your equipment. Choosing the right 3-core flat cable can distinguish between seamless performance and costly downtime. These specialized cables, with their three conductors arranged in a flat, ribbon-like design, are built for durability and flexibility, making them ideal for demanding environments like submersible pumps, manufacturing plants, and heavy machinery setups. We understand the importance of reliable wiring solutions at BCH Electric Limited, a trusted name in India’s electrical industry since 1965. Our 3 core flat cables are designed to meet rigorous standards, ensuring safety, efficiency, and longevity for your projects.

But with so many options available, how do you select the right cable for your specific needs? It’s not about picking up any cable off the shelf. It’s about understanding your application, environment, and technical requirements. Whether wiring a factory floor or setting up an irrigation system, the right 3-core flat cable ensures optimal performance and minimizes risks like overheating or electrical faults. In this article, we’ll break down the key factors to consider when choosing 3 core flat cables, from conductor materials to insulation types, and share practical tips to help you make an informed decision that keeps your operations running smoothly.

Why 3 Core Flat Cables Matter in Industrial Settings

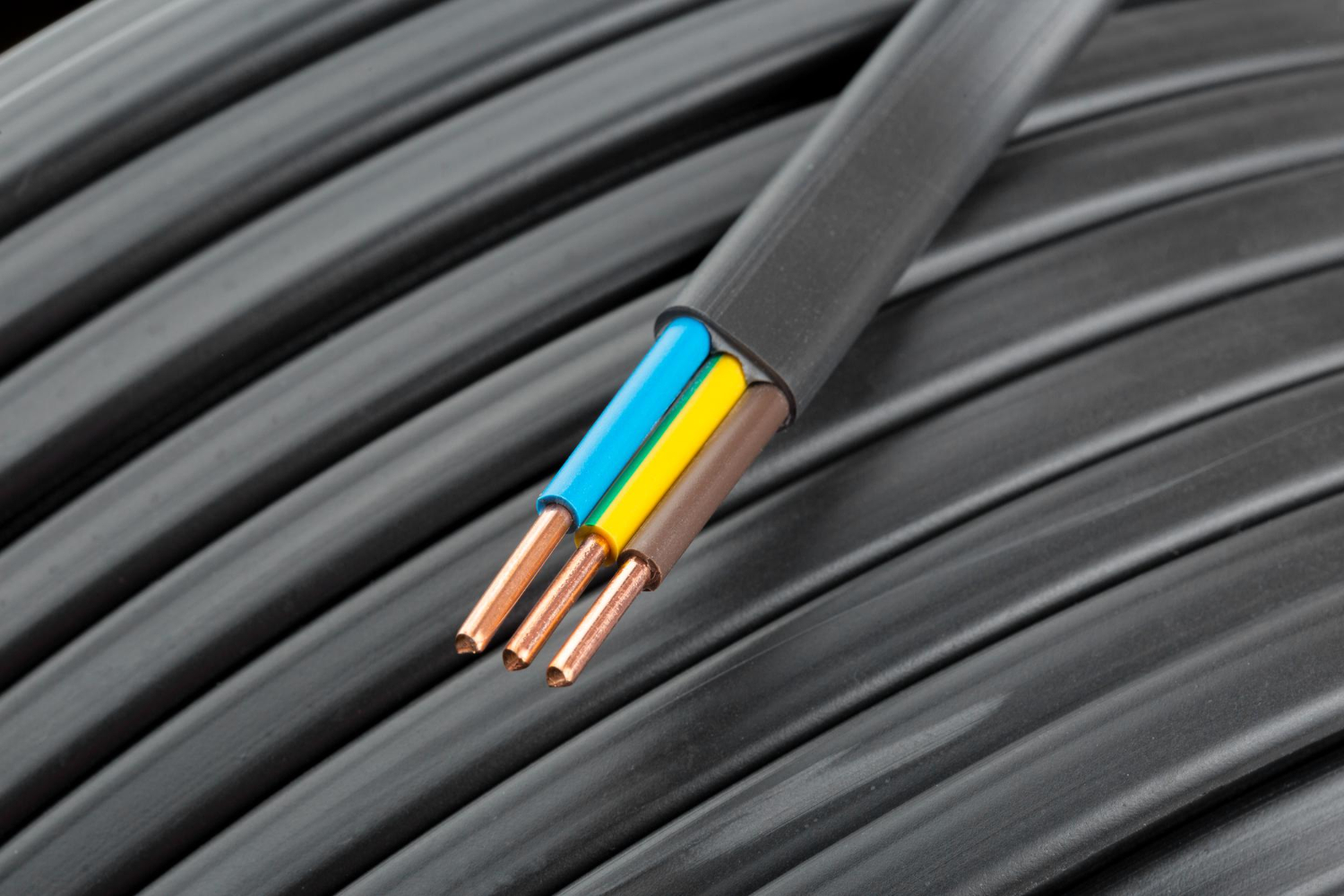

3-core flat cables are a go-to solution for industrial wiring because of their unique design and robust performance. Unlike round cables, their flat configuration allows them to fit into tight spaces, such as narrow conduits or tube wells. This is without compromising power delivery. They’re built to withstand harsh conditions like moisture, abrasion, and extreme temperatures, making them a favorite for submersible pumps and heavy-duty machinery applications. But not all 3 core flat cables are created equal. The wrong choice can lead to inefficiencies, safety hazards, or premature wear, costing you time and money.

Here are five key reasons why 3 core flat cables are critical for industrial wiring:

- Space Efficiency: Their flat design makes installation easier in confined areas.

- Durability: Built to resist water, oil, grease, and abrasion for long-term reliability.

- Flexibility: Easy to route and bend than bulky round cables.

- High Conductivity: Typically made with copper conductors for excellent power transmission.

- Versatility: Suitable for diverse applications, from pumps to solar panel connections.

Key Factors to Consider When Choosing 3 Core Flat Cables

Selecting the right 3-core flat cable involves evaluating several technical and practical aspects. Each factor ensures the cable meets your project’s demands while maintaining safety and efficiency. Let’s dive into the essentials you need to remember.

Critical factors to evaluate:

- Conductor Size: Measured in square millimeters (sq.mm), sizes range from 1.0 to 120.0 sq.mm. Larger sizes handle higher currents but may be less flexible.

- Insulation Type: Options include PVC for standard conditions or XLPE for high-temperature environments up to 90°C.

- Voltage Rating: Ensure the cable is rated for your system’s voltage, typically up to 1100 V for industrial use.

- Environmental Conditions: Consider exposure to moisture, heat, or chemicals, as these affect cable longevity.

- Standards Compliance: Look for cables meeting IS 694 / 2010 and RoHS standards for safety and eco-friendliness.

- Packaging Needs: Choose between coils (100m) or drums (500m or 1000m) based on the project scale.

- Brand Reliability: Choose trusted manufacturers like BCH Electric Limited for quality assurance.

Understanding Conductor Sizes and Their Impact

The conductor size of a 3-core flat cable determines its current-carrying capacity and suitability for your application. Smaller sizes, like 1.5 or 2.5 sq.mm, are ideal for lighter loads, while larger sizes, like 50 or 120 sq.mm, handle heavy-duty equipment. Choosing the wrong size can lead to overheating or insufficient power delivery, so matching the cable to your system’s electrical demands is crucial.

Tips for selecting the right conductor size:

- Calculate your load requirements using the equipment’s power rating.

- Consult a sizing chart or electrician to match current needs with cable capacity.

- Factor in future scalability to avoid replacing cables later.

Insulation Types: PVC vs. XLPE

The insulation material is a game-changer for 3 core flat cables, especially in industrial settings. BCH Electric Limited offers two main types: RoHS-compliant PVC and XLPE. PVC is cost-effective and suitable for standard conditions, while XLPE excels in high-temperature environments, continuously handling up to 90°C. For example, if you’re wiring a factory in a hot climate or a pump under voltage fluctuations, XLPE-insulated cables are the better choice.

Advantages of XLPE insulation:

- High-temperature resistance for demanding environments.

- Better resistance to thermal stress and aging.

- Improved insulation properties for enhanced safety.

- Greater flexibility under fluctuating voltage conditions.

- Reduced risk of insulation breakdown over time.

- Suitable for outdoor or wet applications.

- Enhanced durability against chemical exposure.

- Compliance with RoHS for eco-friendly operations.

- Ideal for heavy-duty industrial machinery.

Environmental and Application Considerations

Industrial environments vary widely, from humid agricultural fields to dusty factory floors. Your 3-core flat cable must withstand these conditions to ensure longevity and safety. Cables for submersible pumps must resist water and abrasion. In high-temperature settings, like steel plants, XLPE insulation is necessary. Continually assess the environment before purchasing to avoid premature cable failure.

Key questions to ask:

What environmental challenges will the cable face (e.g., moisture, heat, or chemicals)?

Observance of Safety Standards and Compliance

Safety is non-negotiable in industrial wiring. 3 core flat cables must comply with standards like IS 694 / 2010, which ensures performance and safety benchmarks. BCH Electric Limited’s RoHS compliance also guarantees lead-free and environmentally friendly cables. Always check certifications to avoid substandard products that pose risks.

Safety certifications require:

- IS 694/2010 for performance and reliability.

- RoHS compliance for environmental safety.

- ISO 9001:2015 for quality management.

- ISO 14001:2015 for environmental standards.

- ISO 45001:2018 for occupational health and safety.

Practical Tips for Installation and Maintenance

Once you’ve chosen the right 3-core flat cable, proper installation and maintenance are the keys to maximizing lifespan. Incorrect installation can lead to damage or electrical faults, while regular upkeep prevents wear and tear. Here’s how to get it right.

Installation and maintenance tips:

- Use proper tools to avoid damaging the cable during installation.

- Ensure secure connections to prevent loose wiring.

- Protect cables from sharp edges or abrasive surfaces.

- Regularly inspect for signs of wear, especially in wet environments.

- Clean cables to remove dust or grease buildup.

- Avoid overloading the cable beyond its current capacity.

- Consult a professional electrician for complex setups.

Why BCH Electric Limited’s 3 Core Flat Cables Stand Out

BCH Electric Limited has been a trusted name in India’s electrical industry for over 50 years. Our 3 core flat cables reflect our commitment to quality and innovation. Available in standard PVC, XLPE, and thick XLPE variants, our cables cater to various industrial needs, from small-scale pumps to large manufacturing setups. With sizes ranging from 1.0 to 120.0 sq.mm and compliance with IS 694 / 2010, our cables deliver unmatched performance and safety. Our lead-free, RoHS-compliant designs align with modern environmental standards, making them a wise choice for eco-conscious businesses.

Pair Your Cables with BCH Electric’s MCBs for Ultimate Protection

Pair your 3 core flat cables with BCH Electric Limited’s Miniature Circuit Breakers (MCBs) to protect your industrial wiring. Our MCBs are designed to safeguard your electrical systems from overloads and short circuits, offering reliable protection for your equipment and personnel. Available in various ratings, they complement our cables perfectly, ensuring a seamless and secure setup.

Ready to power your next project with confidence? Contact BCH Electric Limited today at our toll-free number, 1800-103-9282, or visit https://bchindia.com/ to explore our full range of products and request a quote. Let us help you build a safe, more efficient electrical system.