Modern factories are evolving rapidly. Automation, Industry 4.0, smart machines, and high-speed production lines demand faster, more reliable, and maintenance-free switching solutions. In this transformation, Solid State Relays (SSRs) are increasingly replacing traditional mechanical relays across industrial applications.

While mechanical relays have served industries reliably for decades, their limitations are becoming more evident in today’s high-performance manufacturing environments. Solid State Relays, with their electronic switching technology, offer clear advantages in speed, durability, safety, and system reliability.

This blog explains why solid state relays are replacing mechanical relays in modern factories, how they work, where they perform best, and why trusted manufacturers like BCH India are playing an important role in this transition.

Understanding the Basics: Mechanical Relay vs Solid State Relay

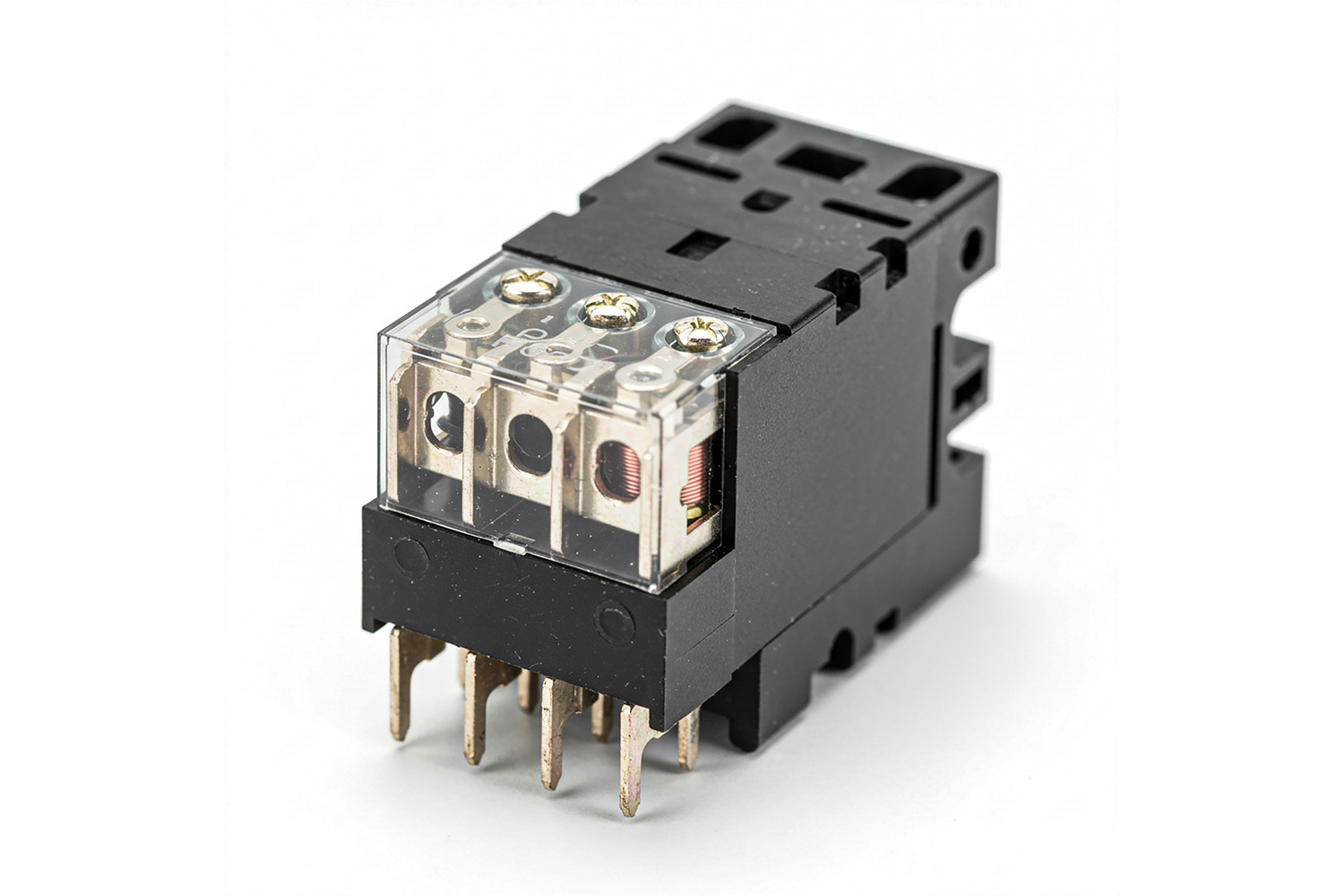

What Is a Mechanical Relay?

A mechanical relay operates using:

-

An electromagnetic coil

-

Moving contacts that physically open and close a circuit

Key characteristics:

-

Audible clicking during operation

-

Mechanical wear over time

-

Limited switching speed

-

Susceptible to vibration and dust

Mechanical relays are still used in low-frequency and non-critical applications, but they struggle in high-speed and continuous-duty environments.

What Is a Solid State Relay (SSR)?

A Solid State Relay is an electronic switching device that uses semiconductor components such as:

-

Thyristors

-

TRIACs

-

MOSFETs

Key characteristics:

-

No moving parts

-

Silent operation

-

Extremely fast switching

-

Long operational life

SSRs switch loads electronically, making them ideal for modern, automated factories.

Why Modern Factories Are Moving Away from Mechanical Relays

Factories today operate under conditions that mechanical relays were never designed for:

-

High switching frequency

-

Continuous operation

-

Harsh industrial environments

-

Precision process control

-

Minimal downtime tolerance

Solid State Relays address these challenges directly.

Key Reasons Solid State Relays Are Replacing Mechanical Relays

1. No Mechanical Wear = Longer Service Life (Experience)

Mechanical relays fail primarily due to:

-

Contact wear

-

Spring fatigue

-

Arcing and pitting

In contrast, SSRs have no moving parts, which means:

-

No contact erosion

-

No mechanical fatigue

-

Significantly longer lifespan

In real-world factory environments, SSRs often last 10–20 times longer than mechanical relays, especially in applications with frequent switching.

This proven durability is a major reason industries are shifting to SSRs.

2. Faster Switching for High-Speed Automation (Expertise)

Mechanical relays typically operate in milliseconds, which limits their suitability for:

-

High-speed machines

-

Pulse control

-

Precision automation

Solid State Relays offer:

-

Microsecond-level switching

-

Precise ON/OFF control

-

Reliable performance in fast processes

This makes SSRs ideal for:

-

PLC-controlled systems

-

Automated assembly lines

-

Packaging and bottling plants

-

Robotics and motion control

3. Silent Operation Improves Work Environment

Mechanical relays produce:

-

Audible clicking noise

-

Vibration during operation

In contrast, SSRs operate completely silently, which is beneficial in:

-

Control rooms

-

Pharmaceutical and food plants

-

Clean rooms

-

Laboratories and testing facilities

Silent operation enhances operator comfort and perceived system quality.

4. Higher Reliability in Harsh Industrial Conditions (Trust)

Factories expose electrical components to:

-

Dust

-

Moisture

-

Vibration

-

Temperature fluctuations

Mechanical relays are vulnerable because moving parts can:

-

Jam

-

Corrode

-

Lose alignment

Solid State Relays:

-

Are sealed devices

-

Have no exposed contacts

-

Are far more resistant to vibration and contamination

This reliability builds long-term trust in SSR-based control systems.

5. Improved Electrical Safety & Reduced Arcing

Mechanical relays generate arcs during switching, which can:

-

Damage contacts

-

Create EMI (electromagnetic interference)

-

Increase fire risk in hazardous environments

Solid State Relays:

-

Switch electronically with minimal arcing

-

Reduce electrical noise

-

Improve overall system safety

This makes SSRs especially suitable for:

-

Hazardous areas

-

Sensitive electronics

-

High-precision control panels

6. Ideal for High Switching Frequency Applications (Authority)

Applications such as:

-

Temperature control

-

Heater control

-

Pulse-width modulation (PWM)

-

Process automation

require frequent ON/OFF switching, sometimes thousands of cycles per hour.

Mechanical relays fail quickly under such conditions, whereas SSRs:

-

Handle high switching frequency effortlessly

-

Maintain consistent performance

-

Reduce maintenance interventions

This capability has made SSRs the industry-preferred solution in modern factories.

Energy Efficiency & Process Stability

Solid State Relays support:

-

Precise control

-

Stable output switching

-

Reduced power fluctuations

In heater and temperature control systems, SSRs:

-

Maintain tighter temperature bands

-

Reduce energy wastage

-

Improve product quality

This aligns with modern factories’ focus on energy efficiency and process optimization.

Mechanical Relays vs Solid State Relays: Comparison Table

| Feature | Mechanical Relay | Solid State Relay |

|---|---|---|

| Switching speed | Slow | Very fast |

| Moving parts | Yes | No |

| Noise | Audible | Silent |

| Life span | Limited | Very long |

| Maintenance | Frequent | Minimal |

| Vibration resistance | Low | High |

| Switching frequency | Limited | Very high |

| Suitability for automation | Moderate | Excellent |

Where Mechanical Relays Are Still Used (Balanced View)

Despite their advantages, SSRs are not a universal replacement.

Mechanical relays are still suitable for:

-

Low-frequency switching

-

Simple control circuits

-

Cost-sensitive applications

-

Situations requiring complete electrical isolation

However, for modern, automated, and continuous-duty applications, SSRs are clearly superior.

Applications Driving the Adoption of Solid State Relays

SSRs are increasingly used in:

-

PLC and automation panels

-

Heater and temperature control systems

-

Packaging and processing machines

-

Injection molding machines

-

Semiconductor manufacturing

-

Food & pharmaceutical plants

-

HVAC control systems

These applications demand speed, precision, reliability, and minimal downtime.

Role of Trusted Manufacturers in SSR Adoption

As factories adopt solid state technology, quality and reliability of SSRs become critical. Poor-quality SSRs can:

-

Overheat

-

Fail prematurely

-

Cause load damage

This is why industries rely on trusted electrical manufacturers.

BCH India: Supporting Modern Factory Automation

With decades of experience in industrial electrical and automation solutions, BCH India has built strong credibility among:

-

Panel builders

-

OEMs

-

Consultants

-

Industrial end users

BCH India’s approach focuses on:

-

Reliable switching solutions for modern factories

-

Products designed for Indian and global industrial conditions

-

Technical transparency and application guidance

The official website https://bchindia.com/ serves as a valuable resource for:

-

Understanding relay and automation solutions

-

Reviewing technical specifications

-

Making informed, application-based decisions

From an EEAT perspective, BCH India demonstrates:

-

Experience through long-term industry presence

-

Expertise via engineering-driven product design

-

Authority through acceptance in industrial automation projects

-

Trust through quality, consistency, and technical clarity

Common Mistakes to Avoid When Switching to Solid State Relays

-

Ignoring heat dissipation requirements

-

Not using proper heat sinks

-

Incorrect load type selection (AC vs DC SSR)

-

Overlooking surge and transient protection

-

Choosing unverified or low-quality SSR brands

Proper selection and installation are essential for long-term success.

EEAT Perspective: Why SSR Adoption Reflects Modern Engineering

-

Experience: Proven reliability in automated factories

-

Expertise: Semiconductor-based switching technology

-

Authority: Widely accepted in Industry 4.0 environments

-

Trust: Predictable performance with minimal maintenance

Solid State Relays represent a mature, future-ready technology aligned with modern manufacturing needs.

Conclusion: Solid State Relays Are the Future of Factory Switching

Solid State Relays are replacing mechanical relays because they offer:

-

Longer life

-

Faster switching

-

Silent operation

-

Higher reliability

-

Better safety

-

Lower maintenance

As factories become smarter and more automated, SSRs are no longer optional—they are essential.

By selecting high-quality SSR solutions from trusted manufacturers like BCH India, industries can build robust, efficient, and future-ready control systems.

For technical insights, application guidance, and product information, professionals are encouraged to explore https://bchindia.com/ before implementing solid state relay solutions.

Need Help Choosing the Right Relay?

If you share:

-

Load type (AC/DC)

-

Current rating

-

Switching frequency

-

Application environment

I can help you select the right solid state relay solution—optimized for safety, performance, and long-term reliability.