In homes, offices, data centers, and factories, overcurrent protection is the first line of defense against electrical fires, equipment damage, and downtime. Two technologies dominate this job: the fuse (the classic, sacrificial device) and the MCB—Miniature Circuit Breaker (a modern, resettable switch). Both interrupt fault current, but they do so differently and with very different ownership costs and maintenance experiences.

This in-depth guide compares MCBs vs fuses across safety, performance, compliance, and lifecycle economics—so you can choose the right protection strategy for new installs, retrofits, and energy-efficient upgrades. We’ll also explain why BCH Electric is widely regarded as one of the best MCB manufacturers in India for residential, commercial, and industrial applications.

Quick Definitions

-

Fuse: A metal element that melts when current exceeds its rated value for a defined time. Once operated (blown), it must be replaced.

-

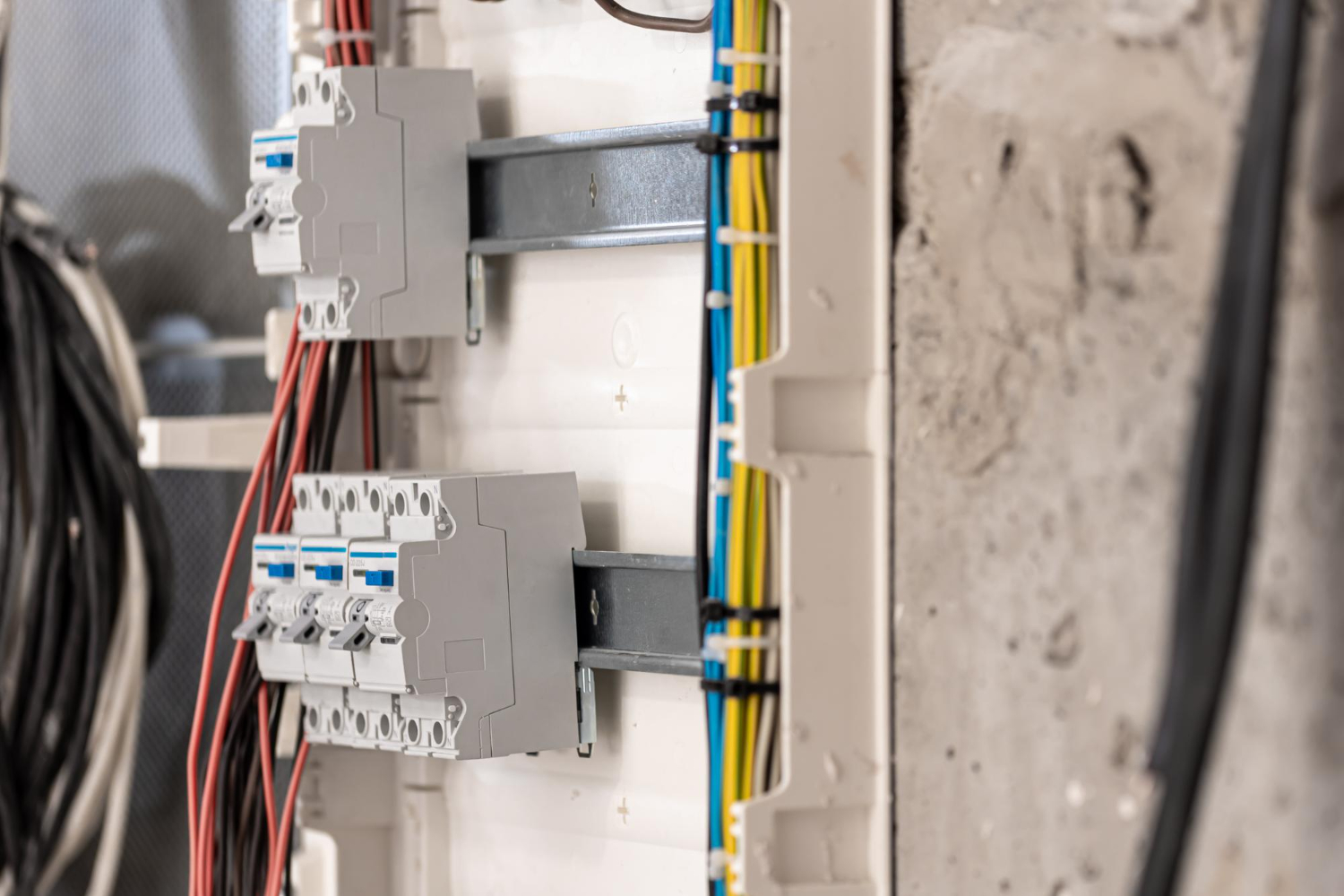

MCB (Miniature Circuit Breaker): An electromagnetic + thermal device that trips on short circuit (magnetic) and overload (thermal). After clearing a fault, an MCB can be reset.

The Big Picture: When to Use What

-

Use MCBs when you need fast restoration, clear trip indication, consistent characteristics, and easier coordination with downstream circuits—typical for modern homes, offices, retail, hospitals, schools, and most OEM panels.

-

Use fuses where you need very high fault-current breaking capacity in a compact, cost-sensitive form, or for special-purpose protection (e.g., semiconductor fuses for drives/rectifiers). In many LV panels, fuses are increasingly paired with MCCBs/MCBs or replaced by them, depending on system design.

Standards & Compliance (At a Glance)

-

MCBs: Typically conform to IEC 60898-1 (final circuits in residential/commercial) and/or IEC 60947-2 (industrial applications).

-

Fuses: Commonly follow IEC 60269 series (gG, aM, etc.).

-

India follows IS/IEC derivatives; selecting devices aligned with these standards supports inspection and audit readiness.

Head-to-Head Comparison

1) Safety & Protection Quality

-

Fuses: Provide excellent current-limiting behavior; high fault currents are cut off quickly due to the element melting. But nuisance operation or wrong replacement ratings can creep in during maintenance.

-

MCBs: Offer dual protection—thermal (overload) + magnetic (short circuit)—with predictable trip curves (B, C, D curves). No replacement risk; you simply reset after clearing the fault cause. Visual ON/OFF/TRIPPED indication helps diagnostics.

Winner for modern systems: MCB (for consistent, user-safe operation and diagnostics).

2) Speed of Restoration & Uptime

-

Fuses: After a fault, you must find the blown fuse, source the correct spare, and replace it—time-consuming, especially in distributed boards.

-

MCBs: Quick reset after fixing the underlying issue. The trip flag helps locate the affected circuit instantly.

Winner: MCB—significantly better for uptime and maintenance efficiency.

3) Selectivity & Coordination

-

Fuses: With proper grading (e.g., gG upstream, aM downstream), fuses can coordinate well, but require careful selection and documentation; field changes can upset coordination.

-

MCBs: Manufacturers provide selectivity/discrimination charts for MCB–MCB and MCB–MCCB combinations. Easier to standardize across a facility; curve selection (B/C/D) supports application tuning (lighting, motors, inrush loads).

Winner: MCB (for ease of engineering and maintaining coordination in multi-tier boards).

4) Total Cost of Ownership (TCO)

-

Fuses: Lower initial device cost but recurring consumable cost (spares inventory, replacement time, human error).

-

MCBs: Higher initial cost per pole than a basic fuse carrier, but no consumables, faster restoration, and fewer human-factor errors. Over the life of a building/facility, MCBs typically reduce TCO.

Winner: MCB in most modern installations.

5) Diagnostics & Smart Panels

-

Fuses: Limited diagnostics; a blown element tells you only that a threshold was exceeded.

-

MCBs: Trip indicators, optional auxiliary contacts (for remote signaling), and compatibility with smart distribution architectures. Easier integration into BMS/SCADA for alarms and energy analytics.

Winner: MCB—future-ready and data-friendly.

6) Handling Inrush & Nuisance Trips

-

Fuses: Time-delay fuses can ride through inrush, but replacement variants must be consistent.

-

MCBs: Choice of B/C/D trip curves matches load profiles:

-

B-curve: Resistive/lighting circuits

-

C-curve: Mixed loads; small motors

-

D-curve: High inrush motors/transformers

-

Winner: MCB for practical, repeatable tuning without part changes.

7) Environmental & Safety in Maintenance

-

Fuses: Opening energized carriers or replacing fuses under poor conditions increases shock/arc risk if procedures aren’t followed.

-

MCBs: Lever operation with clear isolation state; fewer moving parts to touch; safer for non-specialists under supervision.

Winner: MCB—safer handling and clearer status.

Where Fuses Still Shine

It’s fair to note that fuses aren’t obsolete. They remain relevant for:

-

Very high prospective fault currents where compact current-limiting is needed.

-

Semiconductor protection (ultra-fast fuses) in drives/rectifiers to protect sensitive components.

-

Back-up protection in certain coordination schemes with upstream devices.

In many modern boards, however, these niche uses are coordinated with MCBs/MCCBs rather than replacing them across the board.

Choosing the Right MCB: Practical Checklist

-

Rated Current (In): Match to circuit load with headroom for ambient temperature and grouping effects.

-

Breaking Capacity (Icn/Ics): Ensure the MCB’s short-circuit rating meets or exceeds the prospective fault current at the installation point.

-

Trip Curve (B/C/D): Select per load inrush—B for lighting/resistive, C for general, D for high-inrush motors/transformers.

-

Poles: 1P/1P+N (single-phase), 2P, 3P, 3P+N (three-phase).

-

Standards: Look for IEC 60898-1 (res/commercial) or IEC 60947-2 (industrial) depending on application.

-

Accessories: Aux contacts, shunt/undervoltage releases for interlocking, remote trip, or BMS integration.

-

Environmental Ratings: Ambient temperature range, terminal capacity, vibration tolerance, and IP for the enclosure.

-

Selectivity Docs: Prefer brands that publish clear discrimination/selectivity charts with upstream MCCBs.

Installation & Maintenance Best Practices

-

Tighten to Spec: Torque terminals to manufacturer recommendations; re-check during periodic maintenance.

-

Cable Preparation: Use appropriate conductor sizes and ferrules; avoid mixed metals without proper lugs.

-

Derating: Account for temperature, enclosure grouping, and multi-pole adjacency (heat rise).

-

Labeling: Circuit IDs on MCB fronts + updated single-line diagram for quick fault isolation.

-

Periodic Tests: Visual checks, thermal scans in critical panels, and verification of trip accessories/aux contacts.

-

Coordination Review: Whenever loads or upstream devices change, revisit selectivity settings/charts.

Real-World Scenarios

-

Residential Upgrade: Replacing rewirable fuses with C-curve MCBs drastically cuts nuisance trips from appliance inrush and offers faster restoration—reset instead of rewiring.

-

Retail/Commercial: With frequent fit-outs and changing load mixes, MCBs offer flexibility and BMS integration via aux contacts for remote alarming.

-

Industrial OEM Panels: D-curve MCBs for motor feeders reduce false trips at startup; clear trip indication simplifies root-cause analysis for maintenance teams.

Why BCH Electric for MCBs in India?

BCH Electric has earned trust among consultants, contractors, and OEMs by delivering reliable, standards-compliant, and application-ready MCBs designed for Indian conditions:

-

Robust Design & Consistency: Precise thermal-magnetic mechanisms offer stable trip characteristics across B, C, and D curves for a wide range of loads.

-

Strong Breaking Capacities: Models suited for residential, commercial, and industrial boards, aligned with IEC standards for dependable fault clearing.

-

Accessory Ecosystem: Auxiliary contacts, shunt/undervoltage releases, and interlock options support smart distribution and remote diagnostics.

-

Made for Indian Environments: Terminals and housings engineered for heat, dust, and vibration found in real-world installations across India.

-

Service & Availability: Pan-India presence, documentation (selectivity/discrimination guidance), and responsive support make specification, purchase, and after-sales smooth for EPCs and facility teams.

Whether you’re standardizing a new greenfield site or retrofitting legacy boards, BCH Electric’s MCB portfolio helps you hit the sweet spot of safety, uptime, and lifecycle cost.

FAQs

Q1. Are MCBs always better than fuses?

Not always. For semiconductor protection or very high fault levels in compact spaces, specialized fuses excel. For most building circuits and OEM panels, MCBs provide better usability, diagnostics, and TCO.

Q2. Which MCB curve should I pick—B, C, or D?

-

B: Resistive/lighting circuits

-

C: Mixed/general purpose

-

D: High inrush (motors, transformers)

Confirm with measured inrush and system selectivity requirements.

Q3. Do MCBs need periodic replacement?

Generally no, but like all protective devices they should be periodically inspected. Replace if terminals overheat, casing is damaged, or coordination requirements change.

Q4. Can I mix fuses and MCBs in one system?

Yes. Many designs use fuses for specific feeders (e.g., drives) and MCBs for final circuits. Ensure proper coordination and refer to manufacturer selectivity charts.

Q5. How do I size an MCB for a motor?

Consider FLA, starting inrush, and cable size, then pick an appropriate curve (often D). Validate with upstream protection and the motor starter spec.

Conclusion

For most modern electrical systems, MCBs deliver the best blend of safety, speed of restoration, diagnostics, and total cost of ownership. Fuses still have specialized roles, but for the circuits people interact with every day—lighting, sockets, HVAC, small motors, IT/retail loads—MCBs are the pragmatic, future-ready choice.

If you want proven performance with accessible support in India, BCH Electric stands out as a best-in-class MCB manufacturer—combining robust design, standards compliance, and an accessory ecosystem that supports smarter, more reliable panels.

Next step: Share your load list, fault levels, and coordination needs, and I’ll draft a right-sized MCB schedule (ratings, curves, poles, and accessories) tailored to your board—optimized for safety and uptime.